CNC TURNING

We manufacture components such as shafts, pins, flanges, rings, bushings, etc., on turning machining centers

according to the size and requirements of the customer.

Automotive industry

Automotive industry  Aerospace

Aerospace  Engineering industry

Engineering industry  Chemical industry

Chemical industry  Energy industry

Energy industry Basic information

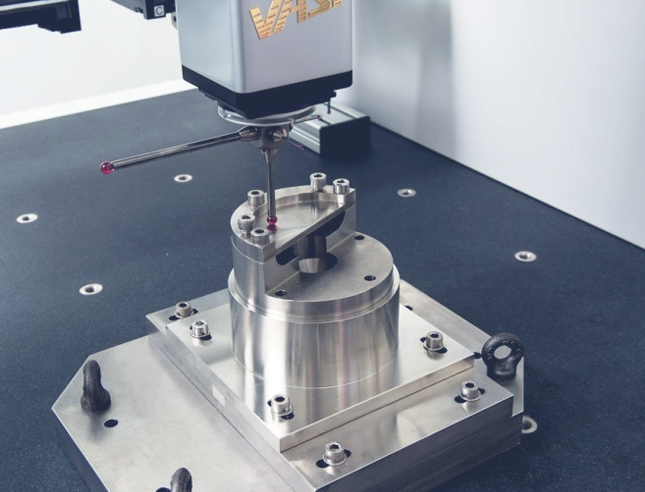

Quality control throughout the entire manufacturing process

An integral part of mechanical manufacturing is precise measurement. Throughout the entire production process, each dimension is thoroughly measured and recorded. Upon request, we can provide an output measurement report for the components.

A wide range of rotary components

We work with 3-axis CNC lathes, capable of machining parts up to 400 mm in diameter, allowing us to produce a wide range of rotary components. From single prototype pieces to hundreds of units. We have six productive CNC lathes with driven tools, on which we can machine a maximum part diameter of 500 mm, a length of 400 mm, and a maximum workpiece weight of 50 kg.

High-precision turning center

We have two productive CNC lathes with driven tools, on which we can machine a maximum part diameter of 400 mm, a length of 1200 mm, and a maximum workpiece weight of 150 kg.

From prototype to serial production

For our customers, we ensure production starting from a single prototype piece up to large-scale production.

Machinery

We work with high-quality machines using the latest technologies in the production process

2x Harrison Alpha 1400XS

Machines of this series are ideal for machining small to medium-sized batches of workpieces with high and rapid repeatability, excellent precision, and surface finishing, all at low production costs.

Working Area

Spindle Speed

Number of Axes

Positioning Accuracy

Center Lathe TOS SV18 RA

The SV18 RA is a tailstock lathe used for all types of turning operations. It is a high-precision and powerful machine, ideal for universal use in single-piece and small-batch production.