Assembly and completion

We provide complete assembly, as well as the assembly of mechanical subassemblies

or the assembly of electrical, pneumatic, and hydraulic components.

Automotive industry

Automotive industry  Aerospace

Aerospace  Engineering industry

Engineering industry  Chemical industry

Chemical industry  Energy industry

Energy industry Basic information

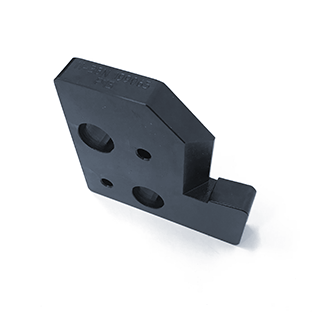

Assembly of components and assemblies

We provide full-scale assembly of machine units, equipment, and components. In addition to manufacturing the required parts, we are also capable of ensuring the complete assembly of the entire system.

Purchased components

We also handle the ordering of purchased parts such as pneumatic cylinders, drives, electric motors, and other components from various suppliers as requested by you.

On-site assembly

The advantage of on-site assembly is the savings on transportation and logistics costs.

There is no need to send individual parts; instead, we deliver the entire ordered system directly.

Assembly of subassemblies is more cost-effective for the customer than just manufacturing individual parts.

Final testing and commissioning

After the machine is completed, we provide testing and commissioning.

We offer service support for the manufactured equipment and can also provide professional training for the operators.

Machinery

We work with high-quality machines using the latest technologies in the production process

Electric thread cutting machine GS 1200-36 E BL

Thread cutting machine with a freely movable arm and parameter adjustment via the built-in display. Additionally, it features a lubrication and blowing function. Angle adjustment: 0 – 90° Quick-release chuck with a slip clutch for safe threading without the risk of breaking the tap. Right-left rotation switch on the machine head. Adjustable lubrication and blowing. Automatic operation: Once the set cutting depth is reached, the machine automatically switches to reverse – ideal for threading multiple blind holes.