CNC MILLING

For CNC milling, we use modern 3-axis and 4-axis machines.

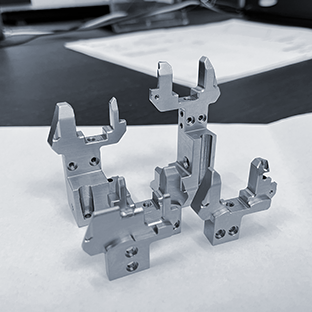

In combination with the CAM solution Fusion360, we are able to machine even geometrically complex parts.

Automotive industry

Automotive industry  Aerospace

Aerospace  Engineering industry

Engineering industry  Chemical industry

Chemical industry  Energy industry

Energy industry Basic information

Multi-axis milling

We have 3-axis and 4-axis machining centers. This allows us to provide production of even the most complex components for our customers.

Quality control throughout the entire production process

Precise measurement is an integral part of mechanical manufacturing. Throughout the entire production process, each dimension is thoroughly measured and recorded. Upon request, we can provide an output measurement report for the components.

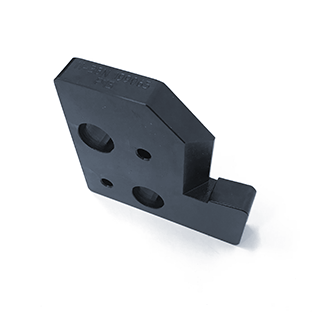

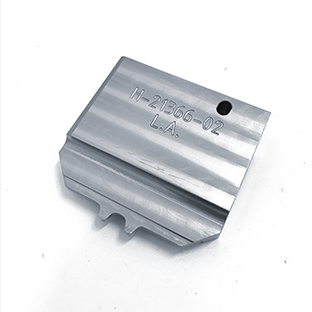

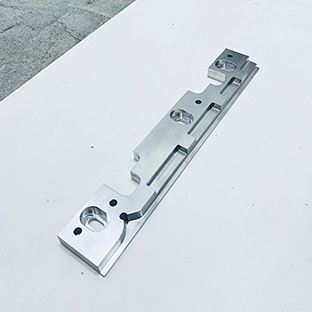

A wide portfolio of manufactured components

We work on high-speed milling centers capable of machining parts up to the size of 1200x530x550mm. We manufacture components for customers from various industries, including – base plates, injection molds, stamping dies, special gears, weldments, castings, fixtures, tools, and more…

From prototype to serial production

For our customers, we ensure production starting from a single prototype piece up to large-scale production.

Machinery

We work with high-quality machines using the latest technologies in the production process

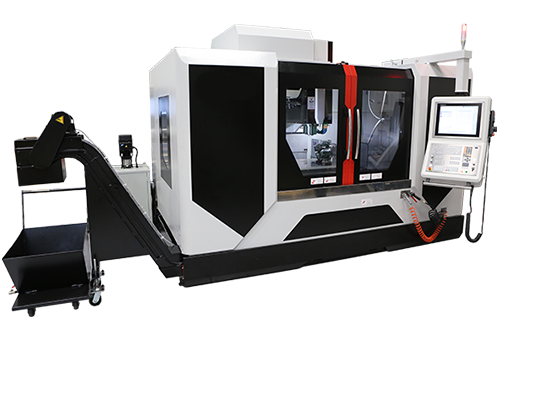

Kopretina TN VMC 1040

High-speed vertical machining centers with high-precision mechanics. Ball bearings and linear guides ensure low noise, high speed, and reliability during high-speed machining. The precise spindle design minimizes thermal distortion effects and ensures sufficient power for heavy-duty machining.

Working Area

Spindle Speed

Number of Axes

Positioning Accuracy

Strojtos VMC50

The VMC 50 B vertical centers are solid cast, robust milling machines designed for a wide range of milling operations in both single-piece and serial production, including mold-making work.